Biopolymers (NAWAROH®)

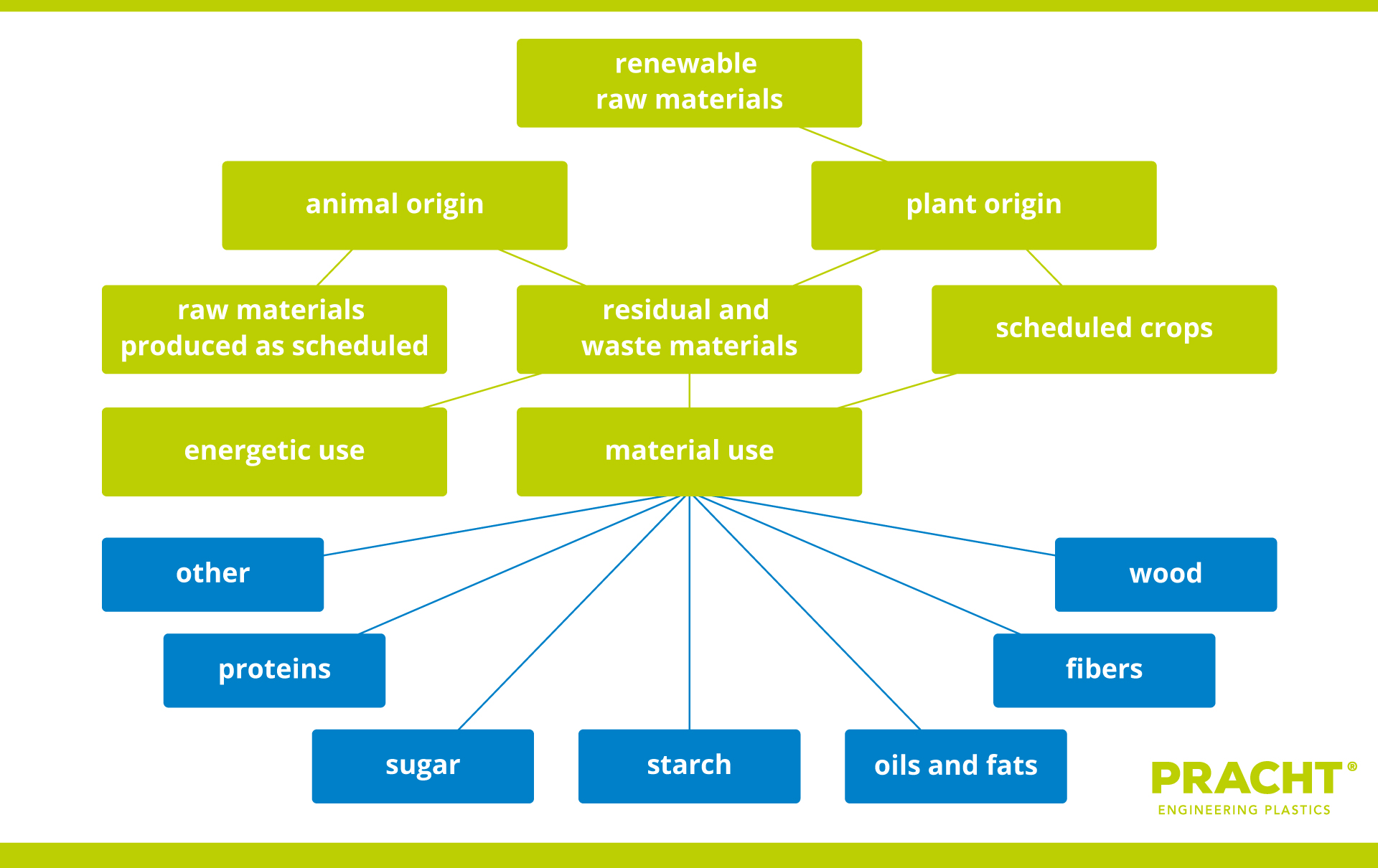

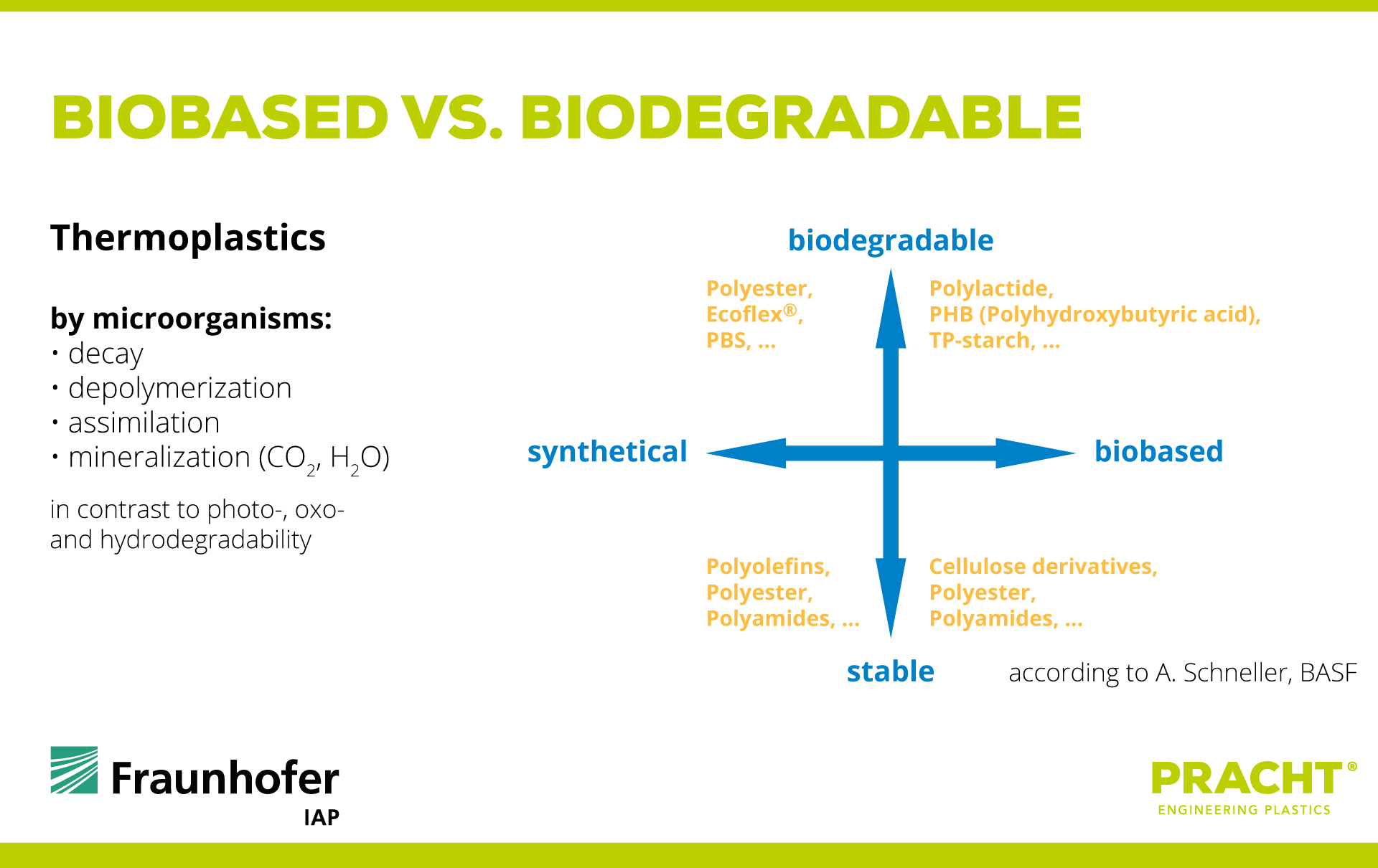

Biopolymers are partly or completely composed of NAWAROH®, renewable raw materials or other raw materials shown in the diagram. A further distinction is made between biodegradable and resistant materials. Biopolymers are increasingly used as so-called “drop in” solutions, i.e. a replacement of the known engineering plastics by Biopolymers takes place. With regard to ethics the variant of extraction from food is not only discussed at the level of science. Just as with Thermoplastics, a distinction is made between applications in technical sectors or in consumer applications or even in the use of packaging. The performance profiles differ in the key areas as resistance, impact strength, temperature behaviour, electrical characteristics etc. The prices per kg also deviate significantly.

Basic characteristics of biobased polymers

- compared to synthetic polymers of the same family with equivalent characteristic profiles petrolium-independent

- muliple usability > refurbishing

- products with technical durability

- suitability for environmentally sound recycling and disposal [Fig. 1]

- organizational measures in compliance with the law

- CO2 neutral

Typical applications

- „drop in” application as a substitute for petroleum-dependent polymers in high-tech applications

- packaging foils

- yoghurt cups made of PLA (polylactic acid)

Technical options

- process technology in injection molding and extrusion processes

- transparent covers in LED technology

- increased impact strength due to fillers

Machinery – Clamping force range / injection unit

Clamping force from 50 to 150 to, injection unit in accordance with EUROMAP